D Fender Wysoka absorpcja energii Łatwa instalacja Ekonomiczne Odporność na warunki atmosferyczne Oszczędność miejsca

Opis

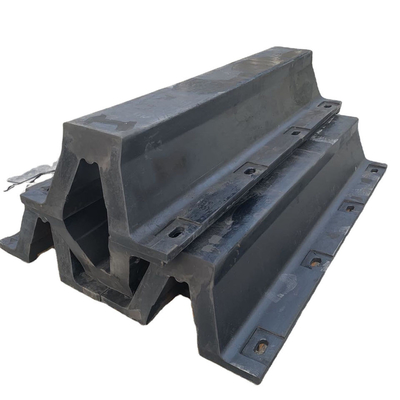

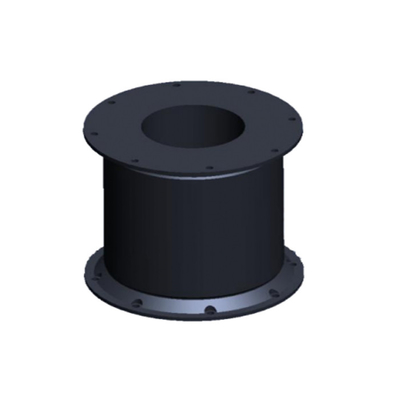

Odbojnica gumowa dokowa typu V została specjalnie zaprojektowana do pochłaniania energii uderzenia statków podczas cumowania, zapewniając doskonałą ochronę zarówno statkom, jak i konstrukcjom dokowym. Wykonana z najwyższej jakości związków gumy syntetycznej, ta odbojnica łączy w sobie elastyczność i trwałość, aby wytrzymać trudne warunki morskie, w tym korozję słoną wodą, ekspozycję na promieniowanie UV i ekstremalne temperatury. Jej unikalna konstrukcja w kształcie litery V zapewnia optymalne rozpraszanie energii podczas operacji dokowania, zmniejszając ryzyko uszkodzeń konstrukcyjnych i zapewniając płynne cumowanie.

Kluczowe zalety

Wysoka zdolność pochłaniania energii dla średnich i dużych statków.

Doskonała odporność na zużycie i długa żywotność.

Elastyczne opcje instalacji na różnych typach doków.

Zmniejszone wymagania konserwacyjne w porównaniu z tradycyjnymi odbojnicami.

Studium przypadku

W porcie w Rotterdamie odbojnica gumowa dokowa typu V została zainstalowana wzdłuż ruchliwego terminalu kontenerowego. W ciągu sześciu miesięcy operatorzy terminalu odnotowali znaczny spadek uszkodzeń spowodowanych uderzeniami statków o dok. Kształt V odbojnicy umożliwił kontenerowcom o pojemności do 20 000 TEU bezpieczne cumowanie w zmiennych warunkach pływowych, potwierdzając jej niezawodność i wydajność w portach o dużym natężeniu ruchu.

Specyfikacje

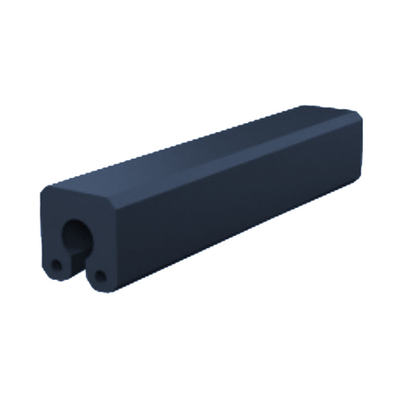

| Miejsce pochodzenia |

Chiny |

| Nazwa produktu |

Odbojnica gumowa dokowa |

| Typ |

Typ w kształcie litery D |

| Usługa przetwarzania |

Formowane kompresyjnie |

| Kolor |

Czarny (więcej kolorów opcjonalnych) |

| Materiał |

Gładki NR |

| Wydajność |

Doskonała właściwość chemiczna i fizyczna |

| Logo |

Życzenie klienta |

| Zastosowanie |

Port, dok, łódź |

| Typ |

Specyfikacje |

| H |

B |

L |

Otwory |

Q |

C |

h |

D |

d |

| D150x150x1000 |

150 |

150 |

1000 |

3 |

350 |

150 |

25 |

40 |

24 |

| D200x200x1000 |

200 |

200 |

1000 |

3 |

353 |

150 |

35 |

55 |

30 |

| D200x200x3000 |

200 |

200 |

3000 |

8 |

400 |

100 |

35 |

55 |

30 |

| D250x250x1000 |

250 |

250 |

1000 |

3 |

350 |

150 |

35 |

60 |

30 |

| D250x250x3000 |

250 |

250 |

3000 |

8 |

400 |

100 |

35 |

60 |

30 |

| D300x300x1000 |

300 |

300 |

1000 |

3 |

350 |

150 |

40 |

65 |

32 |

| D300x300x3000 |

300 |

300 |

3000 |

8 |

400 |

100 |

40 |

65 |

32 |

| D300x360x1000 |

300 |

360 |

1000 |

3 |

350 |

150 |

40 |

65 |

32 |

| D300x360x3000 |

300 |

360 |

3000 |

8 |

400 |

100 |

40 |

65 |

40 |

| D400x400x1000 |

400 |

400 |

1000 |

3 |

400 |

150 |

55 |

80 |

32 |

| D400x400x3000 |

400 |

400 |

3000 |

8 |

400 |

100 |

55 |

80 |

40 |

| D500x500x1000 |

500 |

500 |

1000 |

3 |

350 |

150 |

90 |

97 |

45 |

| D500x500x3000 |

500 |

500 |

3000 |

8 |

400 |

100 |

90 |

97 |

45 |

| DANE TECHNICZNE |

| WŁAŚCIWOŚCI |

NORMA TESTOWA |

WARTOŚCI |

| Związek |

- |

NR / SBR |

| Gęstość (ciężar właściwy) |

DIN 53505 |

1200 kg/m3 |

| Wytrzymałość na rozciąganie |

DIN 53504 |

≥16 MPa |

| Wydłużenie przy zerwaniu |

DIN 53504 |

≥350% |

| Odporność na rozdarcie (23°C) |

DIN 53507 |

≥80 N/cm |

| Odporność na ścieranie |

DIN 53516 |

≤100mm3 |

| Odkształcenie ściskające (24h @ 70°C) |

DIN 53517 |

≤40% |

| Odporność na ozon (ppm 20% 72h @ 40°C) |

ISO 143/1 |

Brak pęknięć widocznych gołym okiem |

| Zmiana twardości |

DIN 53504 |

≤5° |

| Zmiana wytrzymałości na rozciąganie |

DIN 53504 |

≥80% |

| Zmiana wydłużenia przy zerwaniu |

DIN 53504 |

≥80% |

| Temperatura minimalna |

- |

-30°C |

| Temperatura maksymalna |

- |

+70°C |

Cechy

Wysoka wydajność pochłaniania energii

Odbojnica typu V została zaprojektowana z geometrią, która maksymalizuje pochłanianie energii podczas cumowania. Kształt V kompresuje się przy uderzeniu, równomiernie rozkładając siły i zmniejszając lokalne naprężenia na ścianach doku. Obszerne testy w symulowanych warunkach cumowania pokazują, że te odbojnice mogą pochłaniać do 40% więcej energii niż tradycyjne prostokątne odbojnice, chroniąc statki przed uszkodzeniem kadłuba i zapewniając bezpieczeństwo operacyjne.

Trwały związek gumowy

Hongruntong Marine wykorzystuje specjalną mieszankę gumy syntetycznej, która zapewnia wyjątkową odporność na ścieranie, promieniowanie UV i korozję słoną wodą. Zapewnia to, że odbojnica zachowuje swoją integralność strukturalną przez długi czas, nawet w najtrudniejszych warunkach morskich. W testach laboratoryjnych materiał zachował ponad 90% swojej pierwotnej elastyczności po 5 latach ciągłej ekspozycji na warunki morskie na zewnątrz.

Elastyczna instalacja konserwacja

Nasze odbojnice typu V mogą być instalowane pionowo lub poziomo, w zależności od wymagań doku. Modułowa konstrukcja pozwala na szybką wymianę poszczególnych sekcji, minimalizując przestoje. Dodatkowo odbojnice wymagają minimalnej konserwacji, a regularne czyszczenie wodą i łagodnym detergentem wystarcza do utrzymania optymalnej wydajności.

Ekologiczne i ekonomiczne

Trwała konstrukcja odbojnic zmniejsza potrzebę częstej wymiany, obniżając koszty operacyjne w czasie. Ponadto nietoksyczny skład gumy zapewnia zgodność z przepisami ochrony środowiska, minimalizując ryzyko zanieczyszczenia w wrażliwych obszarach portowych.

Zastosowania

Komercyjne terminale kontenerowe

Odbojnice typu V zapewniają wyjątkową ochronę dużym kontenerowcom podczas cumowania. Zmniejszają ryzyko uszkodzenia kadłuba, zapewniają bezpieczeństwo operacji przeładunku ładunków i wydłużają żywotność infrastruktury dokowej.

Pirsy promowe dla pasażerów

W terminalach promowych o dużym natężeniu ruchu odbojnice te skutecznie pochłaniają powtarzające się uderzenia podczas cumowania, zachowując integralność strukturalną i zapewniając bezpieczeństwo pasażerów podczas wsiadania i wysiadania.

Obiekty portowe przemysłowe

Porty przemysłowe obsługujące tankowce, masowce lub statki transportujące ładunki ogólne korzystają z wysokiej absorpcji energii odbojnic typu V i odporności na korozję chemiczną, zapewniając nieprzerwaną pracę nawet w trudnych warunkach przemysłowych.

Dlaczego warto wybrać Hongruntong Marine?

Zaawansowane badania i rozwój oraz innowacje produktowe

Hongruntong Marine intensywnie inwestuje w badania i rozwój, stale optymalizując konstrukcje odbojnic. Nasze odbojnice typu V są wynikiem obszernych symulacji i testów w rzeczywistych warunkach, zapewniając maksymalną absorpcję energii, trwałość i wydajność. Nasze laboratoria wewnętrzne testują każdą partię pod kątem wytrzymałości na rozciąganie, odporności na ściskanie i degradacji UV.

Kompleksowa kontrola jakości procesu produkcyjnego

Każda odbojnica jest produkowana przy użyciu precyzyjnych technik formowania, a następnie poddawana rygorystycznym kontrolom jakości. Od wyboru surowców po dostawę końcową, każdy etap jest monitorowany pod kątem zgodności z normami ISO 9001. Losowe testy partii zapewniają stałą jakość produktu w przypadku wdrożeń na dużą skalę.

Sprawdzona historia z globalnymi klientami

Odbojnice Hongruntong Marine cieszą się zaufaniem portów na całym świecie. Godne uwagi instalacje obejmują Port w Rotterdamie, Port w Szanghaju Yangshan i Przemysłowy Port w Abu Zabi. Rekomendacje klientów podkreślają niezawodność naszych produktów, długą żywotność i wydajność w ekstremalnych warunkach pogodowych i przy dużym natężeniu ruchu statków.

Profesjonalne wsparcie i serwis posprzedażny

Oferujemy pełne wsparcie techniczne, od wskazówek dotyczących instalacji po szkolenia konserwacyjne. Nasz serwis posprzedażny zapewnia szybką reakcję na wszelkie problemy operacyjne, z łatwo dostępnymi częściami zamiennymi i dedykowanym zespołem serwisowym monitorującym wydajność. To zaangażowanie gwarantuje satysfakcję klienta i długoterminowe partnerstwo.

FAQ

1. Jakie rozmiary są dostępne dla odbojnic gumowych dokowych typu V?

Nasze odbojnice typu V są dostępne w różnych rozmiarach, odpowiednich dla małych, średnich i dużych statków. Dostępne są również niestandardowe wymiary w oparciu o specyficzne wymagania portowe.

2. Jaka jest żywotność odbojnic?

Przy odpowiedniej konserwacji odbojnica typu V może wytrzymać 8–15 lat, w zależności od warunków środowiskowych i intensywności użytkowania.

3. Czy odbojnica może być używana w ekstremalnych temperaturach lub trudnych warunkach pogodowych?

Tak, syntetyczny materiał gumowy został zaprojektowany tak, aby wytrzymywał temperatury od -40°C do 70°C i pozostaje odporny na promieniowanie UV, słoną wodę i zanieczyszczenia przemysłowe.

4. Czy instalacja jest skomplikowana?

Instalacja jest prosta. Zapewniamy szczegółowe instrukcje i wsparcie na miejscu, jeśli jest to potrzebne. Modułowa konstrukcja pozwala na wymianę poszczególnych sekcji bez demontażu całego systemu odbojnic.

Twoja wiadomość musi mieć od 20 do 3000 znaków!

Twoja wiadomość musi mieć od 20 do 3000 znaków! Proszę sprawdzić email!

Proszę sprawdzić email!  Twoja wiadomość musi mieć od 20 do 3000 znaków!

Twoja wiadomość musi mieć od 20 do 3000 znaków! Proszę sprawdzić email!

Proszę sprawdzić email!